60 BPM | High-Speed | Full Servo | Compact & Energy-Efficient

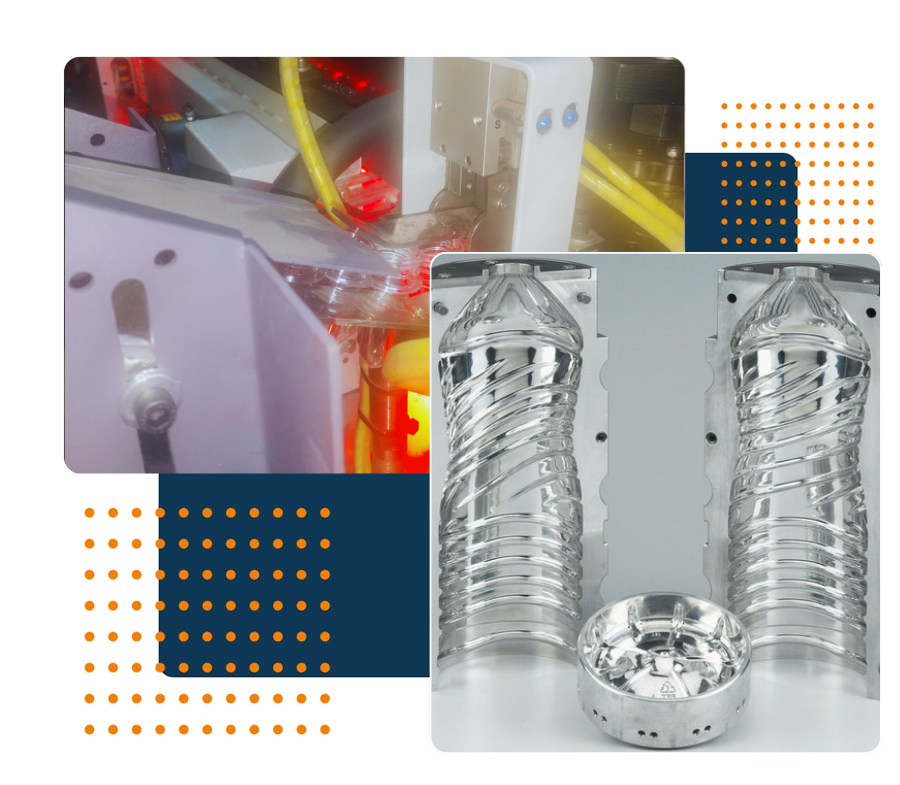

The All-Electrical Servo Series – 60 BPM is a next-generation PET blowing solution built for speed, precision, and energy efficiency. Based on advanced TOP blowing technology, it is engineered with full servo motion on clamping, stretching, and indexing systems. This 2-cavity machine delivers up to 3,600 Bottles Per Hour (BPH) with consistent quality and minimal operational downtime. Ideal for high-output production in mineral water, beverage, and edible oil industries.

Up to 3,600 Bottles Per Hour (BPH) / 60 Bottles Per Minute (BPM)

200 ml to 2 Litres

28 mm / 29/21 mm / Alaska Neck

| Parameter | Specification |

|---|---|

| Machine Type | Fully Automatic, All-Electrical, Servo-Driven (2 Cavity) |

| Technology | TOP Blowing Technology |

| Production Capacity | Up to 60 BPM / 3,600 Bottles Per Hour |

| Bottle Volume Range | 200 ml to 2 Litres |

| Supported Preform Necks | 28mm Alaska, 28mm PCO, 1881/1810 PCO, 29/21 CTC |

| Heating System | 8-Zone Ruby Infrared Pre-Heating Tunnel |

| Stretching & Clamping | Fully Servo-Driven Motion System |

| Control System | Schneider Electric PLC + 7” HMI Touch Panel |

| Electrical Connected Load | Approx. 22 kW |

| Average Running Load | 10–12 kW |

| Air Requirement | 30 Bar (High Pressure), 10 Bar (Low Pressure) |

| Air Consumption | ~35 CFM (with Air Recovery System) |

| Cooling Requirement | 3 TR Chiller – Neck & Mould Cooling |

| Machine Dimensions (L×W×H) | Approx. 4,200 × 1,900 × 2,100 mm |

| Machine Weight | Approx. 3,800 kg |

| Bottle Types | Water, Soft Drinks, Juices, Edible Oils, Detergents |

| Blowing Valve | Seitz / SMC Type with Air Recovery (Up to 40% savings) |

| Optional Features | Neck Orientation, Bottle Counter, Remote Monitoring |

| Utilities Required | HP & LP Compressor, Air Dryer, Air Receiver, Water Chiller |

With advanced technology like full servo clamping, stretching, and loading, and smart features such as infrared heating with 8 optimized zones, our solutions are crafted to meet the demands of modern production environments.

Every bottle shown here is a reflection of our commitment to engineering excellence and operational efficiency.

The official catalog for our premium All-Electrical Servo Series PET Blowing Machines provides comprehensive specifications for 2-cavity, 4-cavity, and 6-cavity models, with output capacities ranging from 60 to 175 Bottles Per Minute (BPM). It includes detailed information on power, air, and utility requirements, along with machine layout diagrams and available upgrade options.

| Feature | Description |

|---|---|

| Pre-Heating | Ruby Infra Infrared – Power-efficient & high-performance |

| Production Output | Up to 3,600 Bottles Per Hour (60 BPM) |

| Servo Motors | Schneider Servo – Dual function for preform transfer & bottle operations |

| Blowing Valve | Switzerland Seitz valve – Includes air recovery, saves up to 40% |

| Stretch Blowing | Servo Top Stretch – Faster mould change & precise bottle control |

| Bottle Transfer | Dedicated Bottle Transfer Mechanism |

| Air Conveyor | Integrated and optimized with blower system |

| Applications | Packaged Drinking Water, Carbonated Soft Drinks, Hot Fill Juice, Edible Oil, Liquid Detergents |

| Supported Neck Types | 28mm Alaska, 28mm PCO, 1881/1810 PCO, 29/21 CTC |

Polyethylene Terephthalate (PET) is used in packaging, textiles, automotive parts, and electronics due to its strength and recyclability. Its diverse applications support innovation and sustainability across multiple industries.

This machine can produce up to 3,600 bottles per hour or 60 bottles per minute (BPM).

It supports a wide bottle volume range, from 200 ml to 2 litres.

It supports various neck options including:

28 mm

29/21 mm

Alaska Neck

Connected Load: Approx. 22 kW

Running Load: Approx. 10–12 kW