Fully Automatic PET Stretch Blow Moulding Machine

Flexible, Efficient, Affordable – Fully Automatic Series

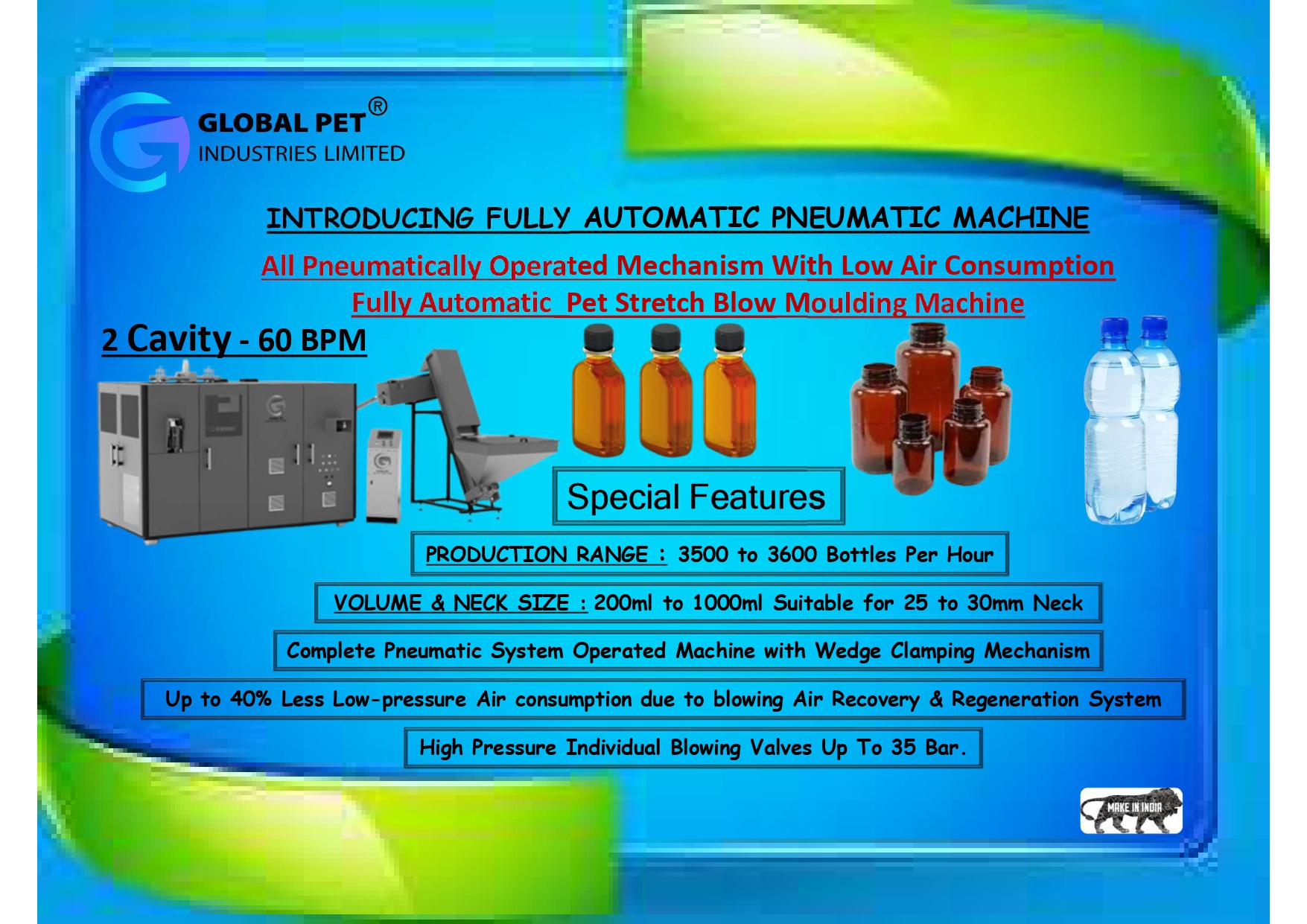

Fully Automatic 2 Cavity Pneumatic Machine

High-Speed PET Bottle Production with Low Air Consumption

Engineered for efficiency, this fully automatic PET stretch blow molding machine operates with a complete pneumatic system and wedge clamping mechanism. With a production capacity of 3500–3600 bottles per hour and compatibility for 200ml to 1000ml volumes with 25–30mm neck sizes, it delivers performance at 60 BPM. Its air recovery and regeneration system ensures up to 40% reduction in low-pressure air consumption, making it a sustainable solution for modern bottling needs.

GPSB-2/1000 for PP & PET Bottles

Versatile Twin-Cavity System for PET and PP Applications

This dual-cavity fully automatic blow molding machine is designed for both PET and PP containers, offering flexibility for a wide range of bottle production. With reliable automation and consistent output, it caters to manufacturers looking for a dependable, efficient solution that handles both material types with ease. The machine supports mid-range production with consistent quality.

GPSB-1/5000 Automatic Jar Machine (Up to 46mm Neck)

Robust Jar Production for Heavy-Duty Applications

Specially built for producing jars with up to 46mm neck size, the GPSB-1/5000 model delivers 700–900 jars per hour. It features a hydraulic mold clamping system that ensures precise forming with minimal parting lines. Infrared heating with an air circulation system guarantees uniform heating for thick-wall preforms, while integrated safety sensors and cooling systems help preserve product quality and operator safety. Ideal for edible oil, chemical, and bulk packaging industries.

Technical Features

- GPSB Series Machines – Two Stage Process Linear type Stretch Blow Moulding Machine with simple & unique designs.

- Schneider PLC – Controlled by high-performance Schneider Electric Modicon M340 PLC with 4MB SD card memory and rugged construction operated by HMI with TFT 7” colour touch screen, supporting more than 2000 recipes and Ethernet/USB ports for connectivity.

- Hydraulic Mould Clamping System – Ensures less than hair parting line in the bottles. Hydraulic Check Valve in Mould holding while blowing process for saving up to 25% electrical power.

- Pneumatic Mould Clamping Unit – Ensures less than hair parting line in the bottles. Pneumatic System and Compensation System is used for operating clamping System with less Air Consumption.

- Infra-Red Heater Reflector with Air Circulating System – Ensures uniform heating of thick wall preforms.

- Sensors & Multiple Security Devices – Highly sensitive sensors are provided to ensure safety of the operator as well as machine.

- Cooling System – In-built cooling system for preform neck, mould & hydraulic oil to avoid neck deformation, filling volume shrinkage & maintain hydraulic oil ambient temperature.

Automatic Preform Feeding System

- Fully Automatic preform feeding system reducing manpower.

- Capacity of up to 7000 preforms at a time ensuring uninterrupted production for at least 1.5 hours.

- Option of 2 to 6 preform feeding at a time.

Integrated Online Air Conveyor System for RFCL Line

- Air conveyors are designed to convey the empty blown PET bottles directly to Rinsing Filling Capping (RFC) Machine from the blowing machine without any manual/human intervention.

- To eliminate manual/human intervention, we provide Bottle Discharge Table & Take-Off unit with Integrated 1 Metre Stainless Steel Air Conveyor with Blower along with pre-filters & blower suitable to carry bottles up to 5 metres for online bottle rinsing filling capping line.

More Product Details

The official catalog for our Fully Automatic PET Stretch Blow Moulding Machines presents complete specifications for high-speed, fully automated models with output capacities of up to 7000 Bottles Per Hour (BPH). It covers bottle sizes from 200 ml to 10 litres, supporting neck finishes of 25 mm, 28 mm, 46 mm, and 120 mm. The catalog includes details on preform feeding, heating zones, clamping systems, air pressure, cooling requirements, and automation options—ideal for water, oil, juice, and household product packaging.

Fully Automatic PET Stretch Blow Moulding Machine – Technical Specifications

| Model | Cavity | Bottle Volume Range | Neck Size | Production Capacity (BPH) | Power Consumption | Preform Heating System | Mould Clamping | Stretching | Special Features |

|---|---|---|---|---|---|---|---|---|---|

| Fully Auto Pneumatic | 2 | 200 ml – 1000 ml | 25 mm – 30 mm | 3500 – 3600 BPH | 18 – 20 kW | Infrared Conveyor with Preheater | Pneumatic Wedge System | Pneumatic | Low Pressure Air Regeneration System |

| GPSB – 2/1000 | 2 | 200 ml – 1000 ml | 25 mm – 30 mm | 2200 – 2400 BPH | 18 – 20 kW | Infrared Conveyor with Preheater | Hydraulic | Pneumatic | PET & PP Bottle Compatibility |

| GPSB – 1/5000 | 1 | 1 Litre – 5 Litre | Up to 46 mm | 700 – 900 BPH | 18 – 20 kW | Infrared Conveyor with Preheater | Hydraulic | Pneumatic | In-built Cooling & Safety System |

Diverse Applications of PETS

Polyethylene Terephthalate (PET) is used in packaging, textiles, automotive parts, and electronics due to its strength and recyclability. Its diverse applications support innovation and sustainability across multiple industries.

Packaged Drinking Water

Soft Drinks (CSD)

Liquid Detergents

Edible Oil Bottling

Hot Fill Juices & Flavored Drinks

Pharmaceutical Liquids & Syrup Bottles

Cosmetic & Personal Care Liquids

Dairy Products (Flavored Milk, Buttermilk)

Water Storage Bubble Top Dispenser

Liquor & Spirits PET Bottles

Fridge Bottles

20 Litre Water Jars

Wide-Mouth PET Jars for Dry & Semi-Liquid Packaging

BPA-Free Baby Feeding Bottles for Safe Infant Care

Heavy-Duty PET Bottles for Agrochemical Packaging

Durable PET Bottles for Lubricants & Engine

Oils

Auto Maintenance FAQs

This machine can produce up to 3,600 bottles per hour or 60 bottles per minute (BPM).

It supports a wide bottle volume range, from 200 ml to 2 litres.

It supports various neck options including:

28 mm

29/21 mm

Alaska Neck

Connected Load: Approx. 22 kW

Running Load: Approx. 10–12 kW